Built With Experience. Refined With Technology.

For more than six decades, Manfredi O&P Affiliates has been designing and fabricating custom lower-limb prosthetics with one goal in mind: helping people move forward with confidence.

We combine time-tested craftsmanship with modern technology — all under one roof — so patients receive thoughtful, individualized care without unnecessary delays.

A Foundation of Craftsmanship

Long before digital tools existed, comfortable, functional prosthetic sockets were built by hand — through careful casting, shaping, and clinical experience. That foundation still matters.

We have been creating purpose-built sockets for over 60 years, using traditional casting techniques when appropriate to capture subtle anatomical detail and ensure comfort. That hands-on experience informs everything we do today.

Technology enhances our process — it doesn’t replace clinical judgment.

Advanced Technology, Used Thoughtfully

As prosthetic technology has evolved, we have remained at the forefront of innovation while staying grounded in what works.

Our in-house technology allows us to:

Capture precise digital images of the residual limb

Create highly accurate socket designs

Make fast, precise adjustments as the body naturally changes over time

By combining advanced CAD/CAM software with traditional fabrication techniques, we’re able to deliver sockets that fit comfortably, function reliably, and evolve with the patient.

Everything is done In-House, Because It Matters.

All prosthetic fabrication is completed in our Eatontown facility. That’s intentional.

Patients deserve:

Adjustments made during appointments

Faster fittings and refinements

Delivery timelines measured in days, not weeks

Whenever possible, fittings and delivery happen within the same week — so patients can continue progressing toward their goals without unnecessary waiting.

Our In-House Technology includes:

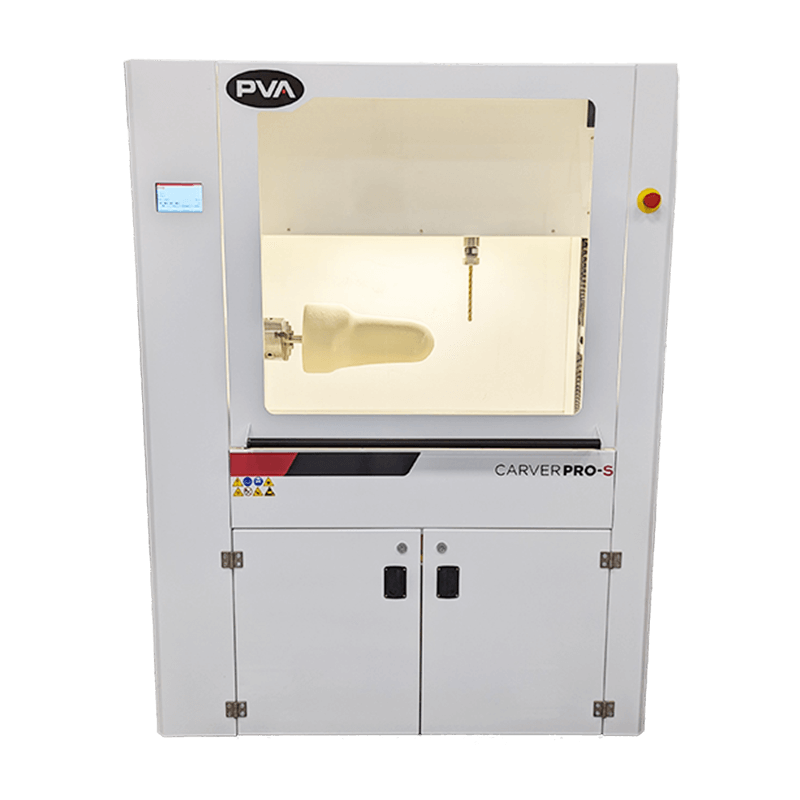

PVA Carver Pro S that create precise replicas of the residual limb

PVA Emergence Pro 3D Printer for producing accurate check sockets

Proteor Icarus Lite 3D printer (introduced in 2025), allowing us to fabricate definitive inner and outer sockets efficiently while maintaining a consistent, proven fit

Our Fabrication Capabilities

We are also among the first in New Jersey, and the only privately owned NJ Clinic, to provide the Limber Prosthetics UniLeg to our patients — a fully 3D-printed below-knee prosthesis.

Navigating Coverage & the NJ Recreational Prosthesis Law

With the support of our experienced In-House Insurance and Billing team, we help patients navigate coverage challenges — including New Jersey’s recreational prosthesis law, passed in 2025.

This law allows eligible patients to receive a second prosthesis designed for recreational use. We assist patients through the entire process and are happy to answer questions or review eligibility.

Comprehensive Lower-Limb Prosthetic Care

We provide custom lower-limb prosthetic solutions at every level, including:

Below-knee (transtibial)

Above-knee (transfemoral)

Hip-level amputations

We maintain relationships with all major component manufacturers worldwide, allowing us to select the right components for each individual — based on lifestyle, goals, and function.

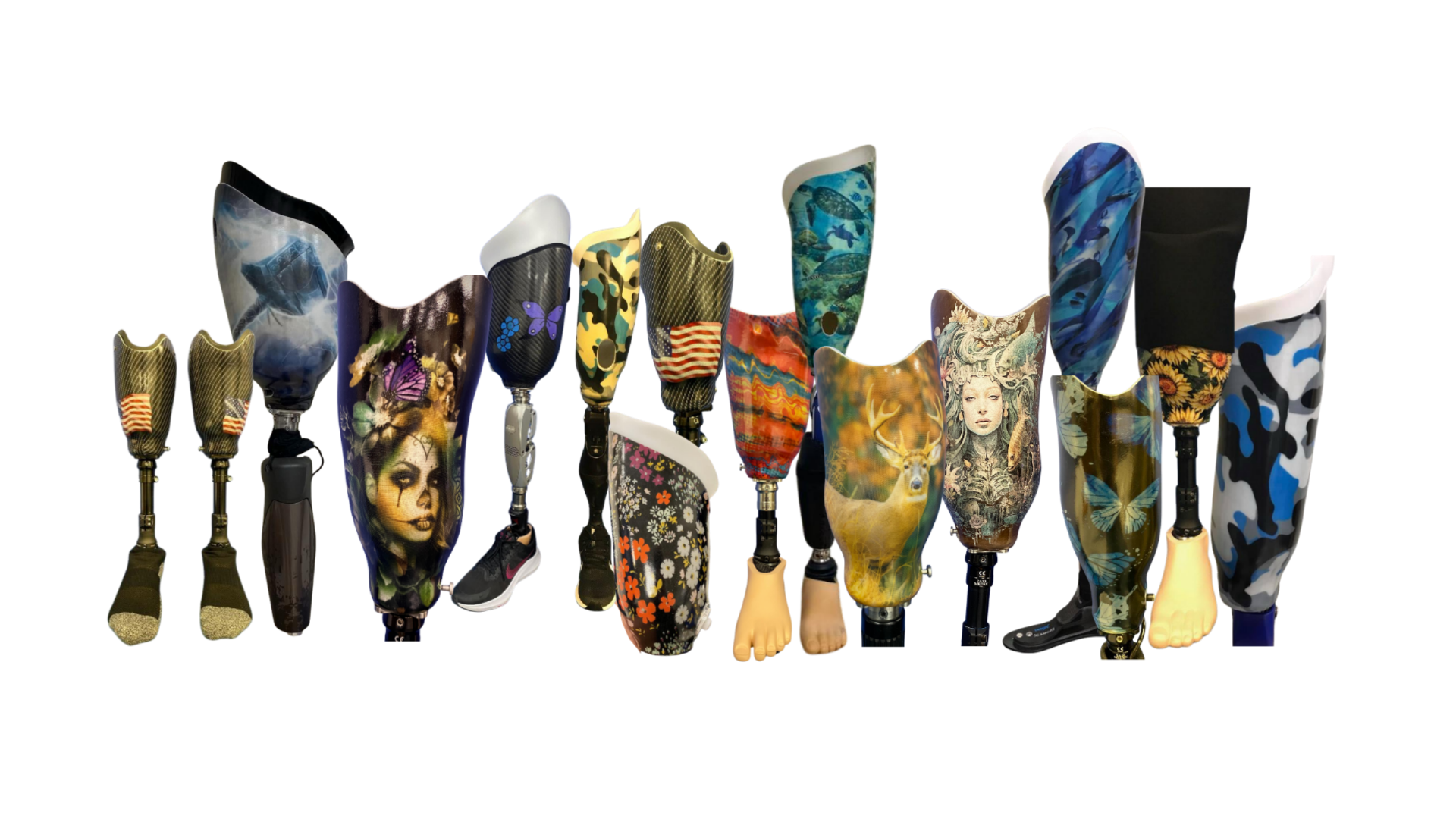

Designed for You

Function matters — but so does identity.

We’re proud to create sockets and prostheses that reflect the individual wearing them. From clean, minimal designs to highly creative custom concepts, we collaborate closely with patients to bring their vision to life.

We also work with select partners who create beautifully designed cosmetic covers for patients seeking a refined aesthetic.

If you can imagine it, we’ll work to build it.